Stainless steel is ubiquitous in daily life: from water cups and tableware to sinks and security windows, it is popular for its corrosion resistance and durability.

However, when you go shopping, you’ll always hear numbers like 201, 304, and 316. What’s the difference between them? Why is there such a big price difference? Today, we’ll explain it all clearly so you can become a shopping expert.

I. Core Difference: A War on “Corrosion Resistance”

Simply put, the main difference between 201, 304, and 316 lies in their different chemical compositions, which directly determines their vastly different “corrosion resistance”.

You can imagine them as three soldiers preparing to go into battle:

• 201 : Ordinary militia, with average equipment, are adequate in mild environments, but are prone to “rusting and surrendering” when faced with strong enemies (such as salt water or acidic substances).

• 304 : Regular troops, well-equipped, capable of handling most complex environments, and the backbone of daily operations.

• 316 : Special forces soldiers, equipped with special gear, remain indestructible even in extremely harsh environments (such as coastal areas or chemical industrial zones).

So what are the “special equipment” that gives them different combat abilities? The answer is alloying elements , especially nickel (Ni) and molybdenum (Mo) .

II. In-depth analysis: Detailed files of the three “soldiers”

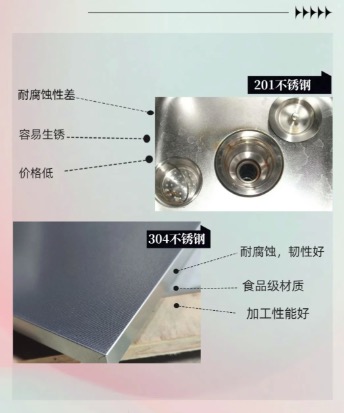

1. 201 Stainless Steel – An Economical and Practical “Backup”

• Composition Revealed : It has a very low nickel content (1-2%) , but in order to maintain the “non-magnetic” or weakly magnetic properties of stainless steel, it contains a large amount of manganese (Mn) .

• Performance characteristics:

• Poor corrosion resistance : This is its biggest drawback. It rusts very easily in humid or salty environments.

Advantages : Inexpensive and low cost.

• Application Scenarios : Primarily used in indoor products for dry environments , such as interior decorative pipes, stair railings, and furniture—areas with low requirements. Not recommended for use in sinks, kitchenware, tableware, or other applications where they come into direct contact with water, acids, or alkalis.

• How to identify : The surface has a duller gloss and a slightly off-white tint. After a period of use, especially in humid environments, rust spots may appear.

2. 304 Stainless Steel – The “Gold Standard” for Household Use

• Composition Revealed : It contains more than 8% nickel (Ni) and more than 18% chromium (Cr) , hence its famous nickname: 18/8 stainless steel . This chromium-nickel ratio achieves a perfect balance.

• Performance characteristics:

• Excellent corrosion resistance : It can resist corrosion from most common media (such as water, air, and acids in food).

• Good processing performance : Easy to form and weld.

• Application Scenarios : This is the mainstream choice for food-grade stainless steel and the first choice for our homes. Water cups, electric kettles, kitchen sinks, tableware, cabinets, and almost any everyday stainless steel product you can think of, 304 should be the first choice.

• How to identify : The surface has a bright metallic luster. Many products will directly laser-mark “304” or “SUS304”.

3. 316 Stainless Steel – Professional-Grade “King of Corrosion Resistance”

• Ingredients Revealed : Based on 304 stainless steel, it contains an additional 2%-3% molybdenum (Mo) . This “molybdenum” is its key ingredient.

• Performance characteristics :

• Extreme corrosion resistance : The addition of molybdenum greatly enhances its resistance to chlorides (such as seawater and salt) and acidic substances, and is especially effective in preventing pitting corrosion.

• Better high-temperature resistance.

• Application scenarios :

• Coastal areas : Doors, windows, railings, etc., can resist the erosion of salty and humid sea winds.

• Medical equipment : Surgical instruments and other fields with extremely high hygiene requirements.

Chemical and shipbuilding industries.

High-end outdoor products and watches.

• How to identify : Similarly, the product will usually be marked with “316” or “SUS316”. Due to its high cost, it is rarely used in low-end daily necessities.

III. A single table for quick summarization

project

201 stainless steel

304 stainless steel

316 stainless steel

core ingredients

High manganese (Mn), low nickel (Ni)

18% Chromium (Cr), 8% Nickel (Ni)

18% Chromium (Cr), 10% Nickel (Ni), 2% Molybdenum (Mo)

Corrosion resistance

Weak and prone to rust

Strong , sufficient for home use

Extremely strong , resistant to acids, alkalis and chlorides

Key elements

Manganese (Mn)

Ni

Mo

price

Cheap

Moderate

expensive

Main applications

Interior decoration, dry environment

Food-grade utensils and kitchen/bathroom equipment (mainstream household use)

Medical, coastal, chemical, high-end products

Common name

none

Food-grade stainless steel

Medical grade stainless steel

IV. Shopping Guide: How to Avoid Wasting Money

1. Check the markings : When purchasing, carefully check the product surface or label for a stamped or indicated “304” or “316”. This is the most direct method.

2. Consider the price : As the saying goes, “you get what you pay for.” If a stainless steel product is unusually cheap, be wary; it may be a counterfeit 201 stainless steel.

3. Select as needed:

• For everyday household use (tableware, water cups, kitchen countertops): 304 is the first choice. It achieves the best balance in performance, price, and safety, and is a “safe material” proven by the market for decades.

• If you live in a coastal area or are exposed to chemicals : If your budget allows, consider 316 stainless steel, which will save you the trouble of rusting later.

• 201 material : Avoid using it to make items that come into direct contact with food, water, or are in a humid environment.

Summarize:

Remember this simple formula: Corrosion resistance = Price: 316 > 304 > 201.

Hopefully, this easy-to-understand explanation will help you make informed choices when purchasing stainless steel products next time, so you won’t be misled by merchants’ advertising!